one-of-a-kind in the market today.

e3 Solutions Patented

Wastewater Evaporation Systems

Each unit has the capability to adjust and control water droplet size to maximize wastewater evaporation efficiency at all times and in all weather conditions. Our wastewater evaporation systems allows for control in the event of uncontrollable weather factors.

Evaporation Technology

Atomizer

In order to improve wastewater system efficiency, reduce maintenance costs, and optimize evaporation, e3 Solutions uses the only rotary atomizer in the global market with:

- 2 HP water–cooled motors.

- Severe duty copper wound.

- Energy consumption rate lower than 1.47 kW.

- Continuous flow rate up to 10 gallons per minute.

- 0 – 15,000 RPM.

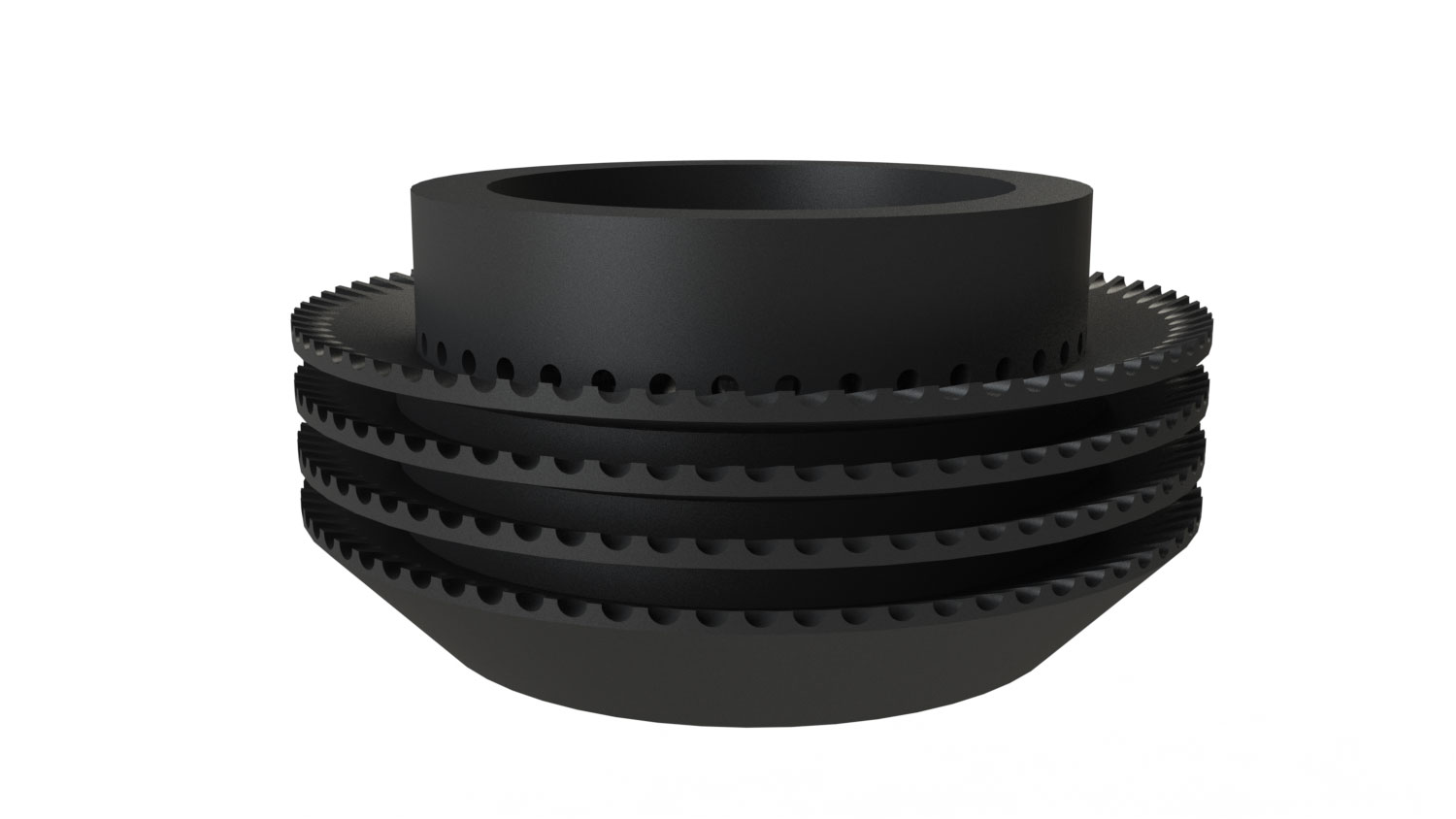

Hub

To mitigate drift and keep water droplets over the wastewater pond footprint, the atomizer and hub create droplet sizes based on real-time wind speed data.

-

Droplet spectra average from 70 – 125 microns.

-

300 serrations and 180 water fracturing outlets.

-

Adjustment and customization of wastewater droplets allow for continuous evaporation and the control of contaminant drift in real-time and as the wind condition changes.

Pump

e3 Solutions wastewater evaporation systems are meant to last, we ensure resistance to saline and inorganic chemicals found in wastewater. Additionally, our evaporator pump is designed to reduce maintenance and enhance overall productivity.

-

Fiber-reinforced plastic and stainless steel components.

-

Permanently lubricated, high-temperature C3 ball bearings.

-

Double internal mechanical seals with silicon carbide faces.

-

Operates at a minimum of 1 HP.

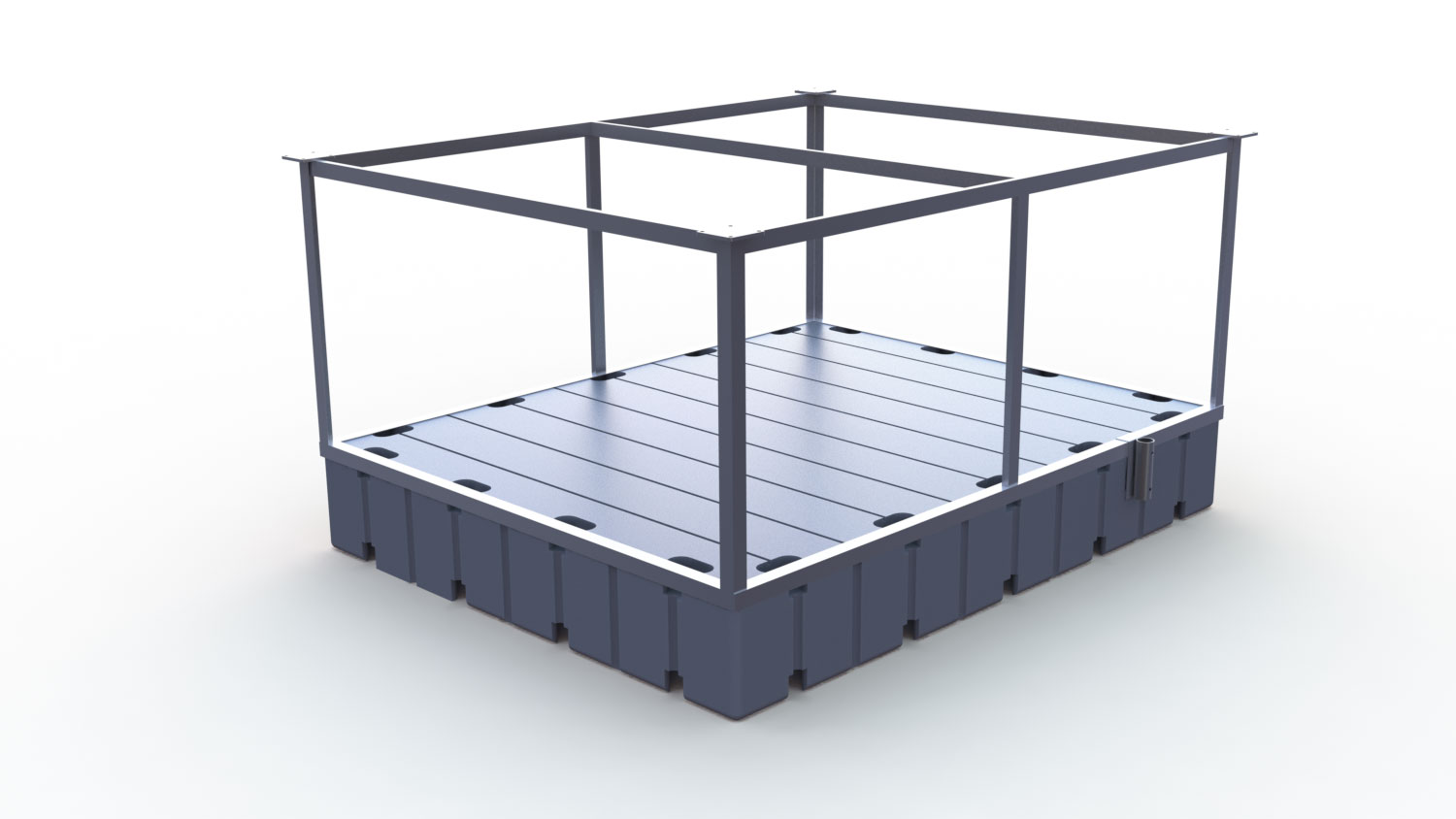

Floating Evaporator Unit

Our floating evaporator is fully assembled, it’s prepared for quick water insertion.

-

Provides a safe servicing platform.

-

Easy installation and setup. Plug-and-play design.

-

Weight: 1100 lbs (500 kg) fully assembled and ready for installation.

-

Wastewater technology made with the most corrosion-resistant materials: 304 stainless steel frame or marine-grade aluminum 6061 frames coated with Nyalic, and polyethylene pontoon filled with 2-part polyurethane foam.

Control Panel

To enhance usability, our wastewater technology’s stainless steel control panel box is easy to use and equipped with the most current evaporation technology.

-

UL certified control panel.

-

Weather-tight NEMA 4X rated.

-

Fan–cooled with a variable frequency drive.

-

Anemometer.

-

Up to three wind–speed ranges.

-

Expandable to operate multiple atomizers.

-

Weather sealed and E-stop installed.

-

Available mounting stand.

Above all, we at e3 Solutions want to help you implement the most high-tech wastewater management technology on the market. Even more so, we don’t want this technology to come at a high cost to your business revenue. Therefore, if you need further information on any product or its components, be sure to contact us.

Maximize wastewater evaporation efficiency FOR

Specific Weather Conditions

Our unique wastewater evaporation systems maximizes the evaporation efficiency by controlling the water flow rates and rotary atomizer speeds for site-specific conditions. Take our free weather analysis below to see how we align with your environmental needs!

Relative Humidity

Dew Point

Air Temperature

Wind Speed & Direction

Because mistreated wastewater is a threat to all living creatures around the world, finding the right wastewater technology is a challenge that every industry faces. That’s where e3 Solutions team of experts steps in!