Oil & Gas: Produced Water Evaporation

Manage produced water at the source with EvaporationWorks’ patented technology designed to reduce disposal costs and environmental impact.

Accelerated Evaporation Technology

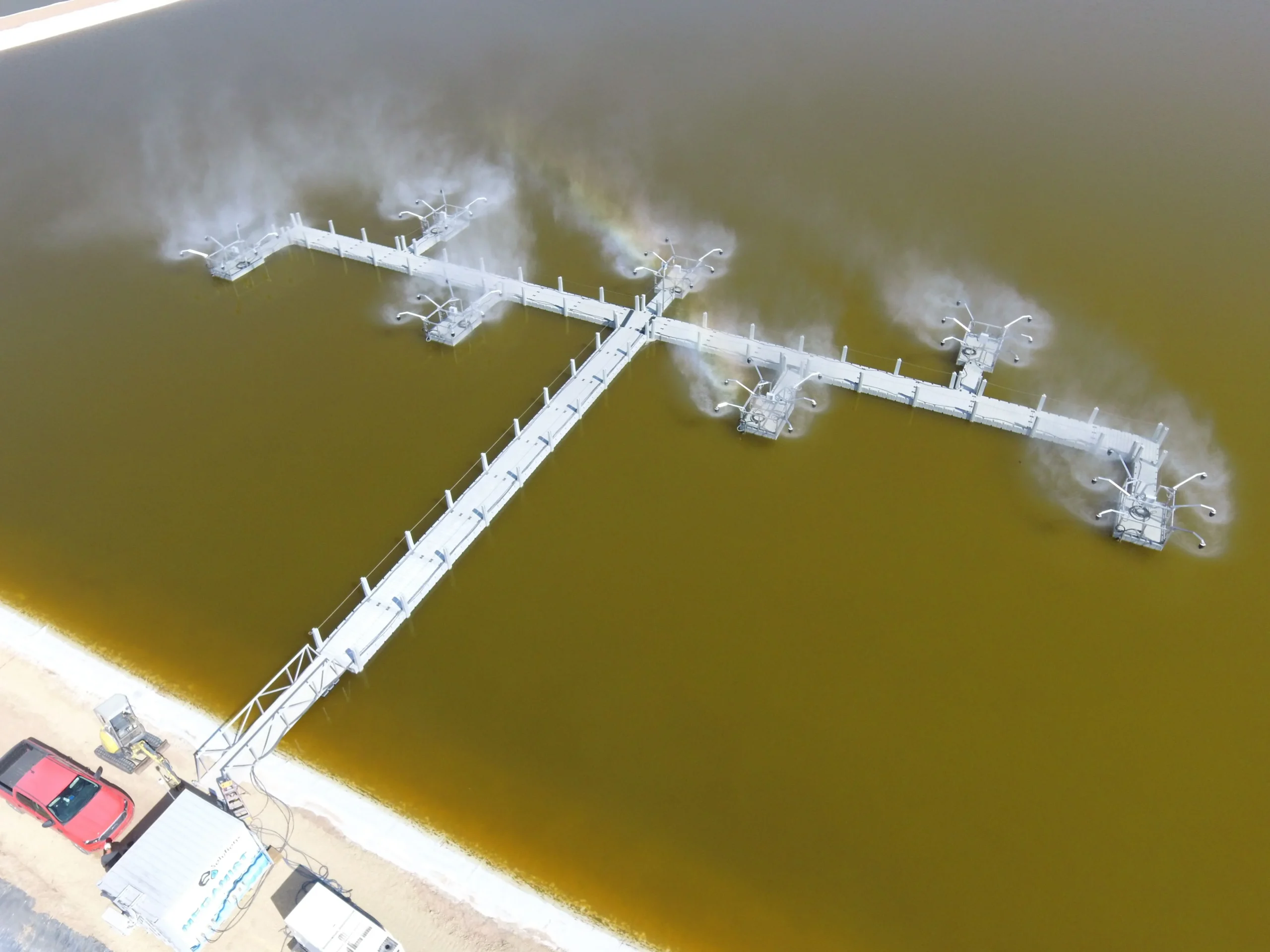

EvaporationWorks offers a proven, scalable approach to produced water management through our enhanced evaporation systems. Our Varimax and MegaMist evaporators are specifically engineered to handle high Total Dissolved Solids (TDS) and Total Suspended Solids (TSS) commonly found in oil and gas wastewater.

Why Operators Choose EvaporationWorks

- Simplified Compliance: Built to help meet zero-discharge and environmental guidelines—without legal gymnastics.

- Flexible for Your Site: Our systems are scalable and customizable to any size facility, from ponds to processing facilities.

- Speed to Results: With fast installation and quick ramp-up, you’re operational in days, not months.

Key Advantages of Our Solutions

Fewer Water Trucks for Lower Hauling Bills

Cut disposal costs by dramatically reducing water volume on-site.

Avoid New Injection Wells

Support your exisitng infrastructure to achieve zero discharge without the permitting and liability headaches.

Automated to Respond to Weather

Built-in sensors adjust performance to real-time conditions, so there's no need for constant oversight.

Common Questions

Accelerated evaporation reduces large volumes of wastewater, including produced water and flowback, at the site. This minimizes the need for hauling, cuts disposal fees, and helps operators meet permit requirements. It is effective in remote areas or regions with limited disposal infrastructure.

Each atomizer has a flow rate of 12 to 20 gallons per minute, depending on site conditions. Systems are modular and can be scaled to match site-specific flow rates or expanded as operations grow.

Yes. By reducing liquid volume at the source, accelerated evaporation significantly lowers the frequency of hauling and associated tipping fees. This delivers major savings for operations facing high logistics costs or disposal limits.

Yes. Our systems reduce discharge volume and support compliance with regulatory requirements for wastewater handling, storage, and treatment.

EvaporationWorks uses a patented rotary atomizer that adjusts droplet size without changing water throughput. This design improves evaporation rates and reduces energy use. Systems are also engineered with minimal moving parts to simplify operation and extend durability.

Permian Basin Case Study

Problem

A leading operator in the Permian Basin was nearing its permitted injection limits.

Produced water volumes were rising, and new wells weren’t a viable option.

The team needed a fast, scalable way to manage growing volumes and avoid operational slowdowns.

Solution

- EvaporationWorks deployed a multi-unit system that allowed the operator to:

Reduce daily injection volumes - Avoid drilling a new Class II injection well

- Stay within environmental permit limits

- Maintain production output without added infrastructure

The system went live within weeks and is now a permanent part of the operator’s produced water strategy.

What Our Clients Say

Compare EvaporationWorks Technology

| Feature | EvaporationWorks | Conventional Industrial Evaporators |

|---|---|---|

| Designed for Produced Water | Built for high TDS/TSS and hydrocarbons | Often retrofitted for oil & gas use |

| Automation & Smart Controls | Real-time, weather-responsive automation | Varies – limited or basic automation |

| Droplet Optimization | Variable-speed atomizer for efficient output | Fixed or limited atomization control |

| Maintenance Requirements | Low-maintenance, rugged design | Higher maintenance in high-solids environments |

| Compliance-Ready | Zero-discharge capable and easy to permit | May require modifications to meet standards |

| Deployment Flexibility | Modular, scalable, site-adaptable | Often requires engineering changes to scale |

| Energy Use Efficiency | Optimized evaporation per kWh | Efficiency varies widely by system |

| Operational Oversight | Minimal supervision needed post-deployment | May require ongoing monitoring or adjustment |

Find Out if Accelerated Evaporation Can Work with Your Oil & Gas Produced Water Solutions

Built-to-fit evaporators for produced water challenges.

Our experts can help you specify the right system for your operation and compliance goals.