e3 Solutions’ patented enhanced evaporation systems are the MegaMist and the Varimax, both specifically designed to effectively evaporate the widest variety of industrial wastewater. The MegaMist and the Varimax feature floating wastewater evaporation systems which sit or float directly on the surface of an impoundment or pond.

- e3’s wastewater management solutions are both effective and worry-free and used for a wide-range of applications, especially where overspray is of concern.

- e3’s MegaMist and Varimax models are the sustainable choice as our patented floating wastewater management technology offers an environmental and economical alternative to truck transport for offsite handling.

- e3’s accelerated evaporators are a natural and efficient way of reducing the amount of fluid that needs to be disposed of and is an economical alternative to costly truck hauling.

- As a leading wastewater evaporation manufacturer, e3 has built systems which require little or no service for thousands of trouble-free operating hours.

- Primary features include a specialized design which is constructed to eliminate the possibility of clogged nozzles, wear issues and high maintenance requirements.

e3’s expertise in the science of water evaporation, including its study of weather factors involved in such natural phenomena, has resulted in development of the highest quality manufacturing materials to utilize the most effective, durable and easy-to-use wastewater evaporators on the market today (download E3’s presentation).

The Varimax and MegaMist can evaporate from naturally occurring stormwater to high TDS and corrosive industrial wastewater without the need of any heat or pressure. e3’s patented evaporation technology is stainless steel, UV stabilized, and chemical resistant, requiring little or no service for thousands of trouble-free operating hours as they eliminate the possibility of clogged nozzles, wear issues and high maintenance requirements seen in other types of evaporator systems.

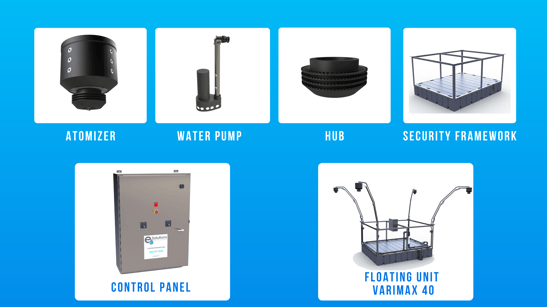

e3’s Wastewater Evaporator System Components and Operation

Both the Varimax and the MegaMist are broken down into the following major modules:

1. Floating Evaporator Unit Composed of:

- Atomizer: e3’s proprietary water-cooled high-speed 2HP motors can rotate from 0 to 15,000 RPM in fractions of a second to adjust the droplet size and control overspray at all times.

- Hub: With 300 serrations and 180 water fracturing outlets, our R&D department developed the most efficient water-fracturing device capable of generating a fine micro-droplet mist averaging between 70 to 120 microns.

- Water Pump: Operating at a minimum of 1HP, our fiber reinforced plastic and stainless-steel water pump ensures resistance to saline and inorganic chemicals found in wastewater. The pump is designed to reduce maintenance and enhance overall productivity thanks to its double internal mechanical seals and permanent lubrication.

- Pontoon and Security Framework: Engineered to support all previously described components. The safe servicing platform is a polyethylene pontoon filled with 2-part polyurethane foam along with a 304 stainless steel frame for easy installation and setup. Plug-and-play design. Plug-and-play design.

2. Control Panel Composed of:

- Electrical Cabinet: UL certified stainless-steel control panel box– 60Hz, 3-phase, 240 volts.

- Variable Frequency Drive: The VFD offers the user versatility by adjusting the atomizer speeds in real-time according to the wind controller settings.

- Wind Controller (Anemometer): With up to three wind-speed thresholds, the anemometer is the fundamental overspray controller allowing to adjust the atomizers speed in real-time and according to current wind conditions (see video).

These combined components make the Varimax and MegaMist the most efficient and reliable wastewater evaporator in the global market. The enhanced wastewater evaporator equipment's versatility and capacity to regulate the size of the atomized water droplet, and the supporting arm design for every atomizer, allows the Varimax and MegaMist to achieve the highest accelerated evaporation efficiencies within the project footprint.

To discuss your specific project needs and find out more about how e3 Solutions can help you, contact us now!